- Color Education

-

Color Knowledge

-

Current position:

Home>

Color Knowledge

difference of colorimeter, density meter, whiteness meter

Each person's feelings and deductive methods of color are very subjective,Different reasons include personal preference, age, eye fatigue and other physiological factors, such as myopia, hyperopia and so on.

So the testing instruments needed for various colors in various industries are also various. First of all, let's talk about the color difference meter.

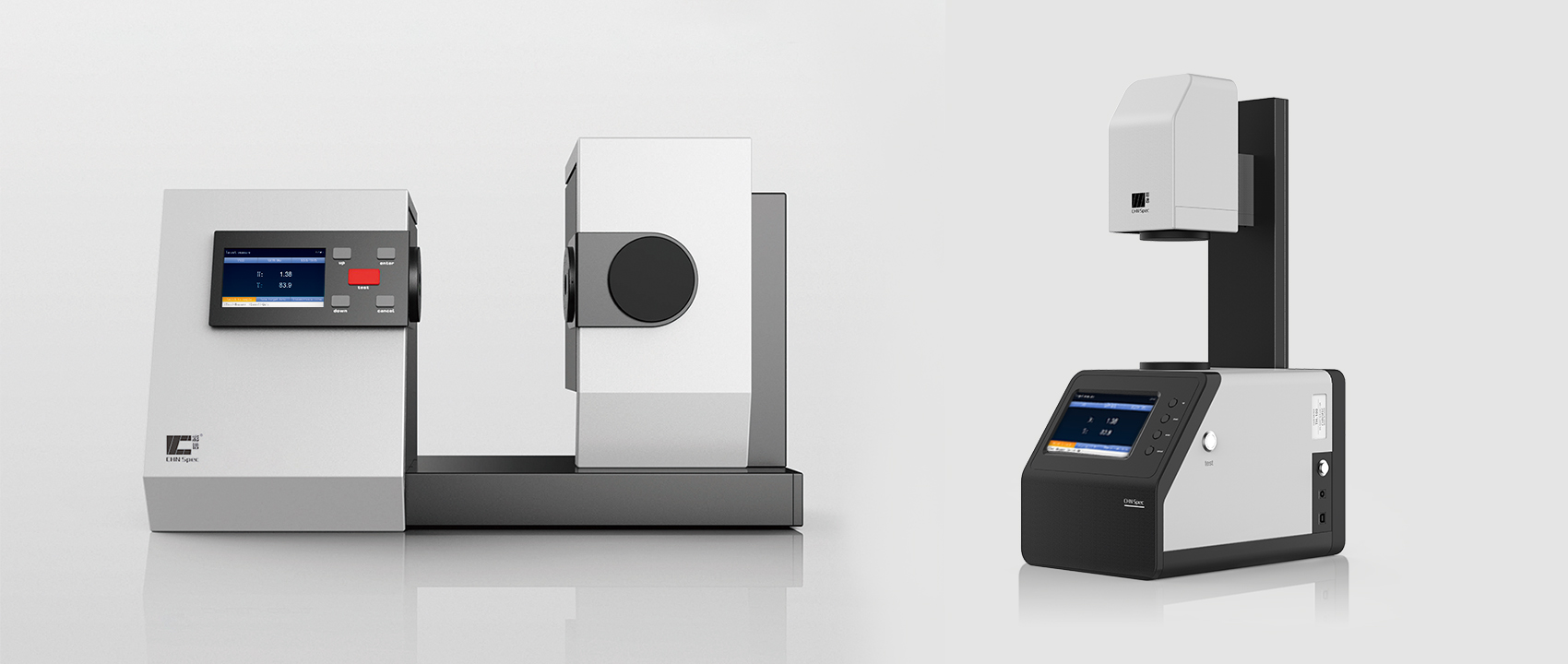

The common colors can be "red", "green" and "blue" in three different colors, and "spell" in different proportions. In order to facilitate the color measurement, the physicist introduced the three stimulus value. According to the colorimetry theory, the color of any color can be expressed by three stimulus values. Therefore, the general color difference instrument's working principle is to collect the reflected light of the sample as the benchmark and measure the three stimulus value of the reflected light of the target sample and the measured sample, and determine the chromatic aberration between the target sample and the sample to be tested. There is a color spectrometer, namely spectrophotometer and color spectrometer is based on the principle of light type design, it can measure the reflectance curve of each wavelength, but also can measure L, accurate a, b value, ratio of general colorimeter is more accurate, stability better. The homemade chromatic aberration instrument, such as CS-220, CS-580 and CS-800 of color spectrum, is suitable for color difference control in various industries such as coatings, plastic, ink, textile, printing and so on.

The second is the whiteness meter. GB/T 17749 "representations of whiteness whiteness of white color characterization object definition degree method", the whiteness value is greater, the greater the degree of white. The whiteness meter uses the integral sphere to measure the diffuse reflectance of the absolute spectrum so that the whiteness is measured. The whiteness of the instrument is used to measure the surface blue whiteness, suitable for textile, printing and dyeing, chemical fiber, plastic, porcelain clay, talcum powder, white cement, paint, paint, enamel, ceramics, paper, paper pulp and other departments should be evaluated on the product whiteness.

The third is the densitometer. The densitometer uses a built-in red, green, and blue light filter to measure the light reflection or transmittance of yellow, fuchsin and green colors and calculate the density value. Density instrument currently used mainly used in the manufacturing industry and all kinds of printing, help comprehensive color from prepress to workshop control.

To sum up, three kinds of color measurement instruments can be used for color quality control, but there are also great differences. The values used are different in different industries. Color difference meter is used for color difference measurement in almost all fields. The color difference between sample and sample is mainly measured, for example, CS-820 can be used for color difference measurement of milk, CS-220 can be used for colloid powder measurement and so on. The whiteness can also be measured, such as the whiteness of the glycosides and the whiteness of Hunter. The whiteness meter is mainly used to measure the whiteness of the surface of the object, and the applicable range is smaller than the chromometer. Densitometer can only measure the density of printed matter, rather than the expression of hue, and can not really reflect the actual visual effect of color, and the application area is also limited.

So the application of the color difference meter is comparatively comprehensive. Hangzhou color spectrum technology Co., Ltd. is a high-tech enterprise specializing in the field of optics, color and other photoelectric measurement technology. It is a good choice to produce color difference meter and spectrophotometer.

-

下载附件

- [Close] [Top] [Print] [Bookmarks]